Magnetic Sound – A brief history of magnetic audio recording

Magnetic recording and storing of data is everywhere in our modern lives. For more than a century magnetic storage has been used in technologies including audio and video tapes, computer hard drives, and the magnetic stripe on the back of bank and phone cards. Magnetic recording has been particularly prevalent in the audio recording industry giving rise to a vast array of different recording formats and technologies.

Top left: Telecom Phone Card [2022.29.13]; Top right: Microsoft Floppy Disk [2017.66.38]; Bottom left: Akai Tape Recorder [2001.22.5]; Bottom left: Sharp VHS Camcorder [2020.25.1]. Museum of Transport and Technology (MOTAT).

How it works

Magnetic recording makes use of changes in the polarity of magnetic materials to create a representation of data. Metal alloys that contain iron (such as steel), or substances such as iron oxides, are used in the manufacture of magnetic recording media due to iron’s high susceptibility to magnetic fields. This susceptibility allows the materials to become polarised when influenced by a magnetic field.

In the case of audio recording, a sound wave is converted to an electrical signal based on vibrations in the air picked up by a microphone. The changing voltage of this signal passes through an electromagnetic recording head, which creates a magnetic field. This magnetic field changes in a similar pattern to the initial sound wave vibrations. When magnetic recording media is passed over the recording head, the media becomes polarised in this same pattern and thus produces a magnetic record of the sound. The process can be reversed and passed through a speaker or amplifier to playback the recording.

The process described here produces an analogue recording where the recorded signal is analogous (similar) to the input signal. All the ups, downs, and in-betweens of the initial sound wave are mimicked in the changing polarity of the magnetic media. A digital audio recording can be created by passing the electrical signal through an analogue-digital converter. This converts the signal to ones and zeroes (North and South polarity) thus encoding it as a binary signal.

Origins

The origins of magnetic recording date to 1888 when American engineer Oberlin Smith published a concept in the journal “The Electrical World”. In response to the relatively new technologies of the telephone and phonograph, Smith proposed that sound waves could be recorded onto a cord or ribbon containing hardened steel by using its magnetic properties. Smith theorised that an electrical signal as produced through a microphone would travel along a coiled wire (solenoid) to produce a varying magnetic field. The recording media would pass through this coil and in turn be imparted with a varying magnetic state analogous to the original audio signal. The recorded sound could then be played back by reversing this process. Short on time and expertise to pursue this concept, Smith published his idea in the hope that one day someone better equipped may produce something useful from it.

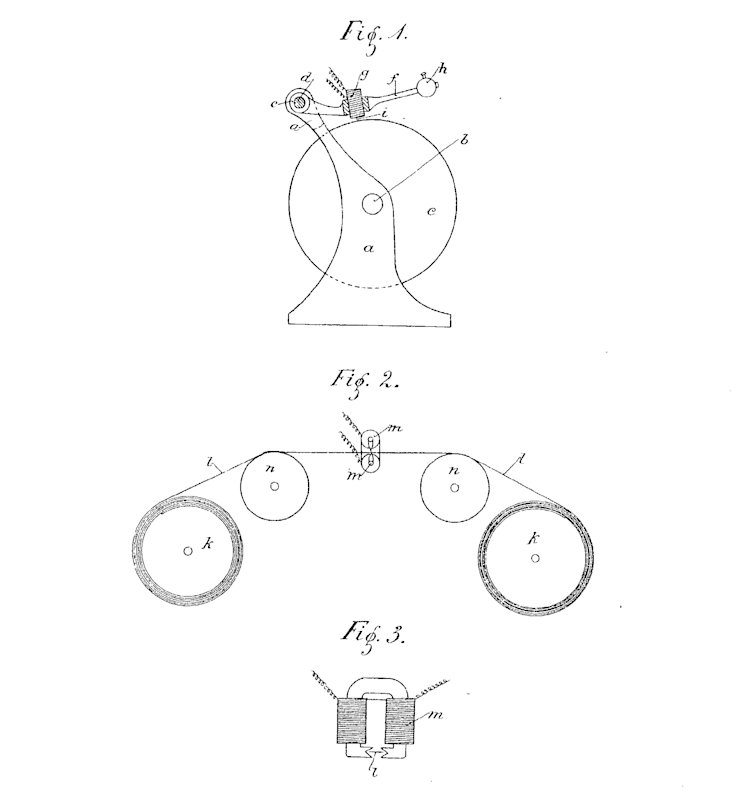

Schematic drawings from Valdemar Poulsen’s original 1899 Danish patent (No.2653)

It wasn’t until a decade later in 1898 that the Danish engineer Valdemar Poulsen is credited with inventing the first functioning magnetic recording device, the Telegrafon. It is unknown whether Poulsen ever read Oberlin Smith’s concept in “The Electrical World” or if he came up with the idea independently. Poulsen’s device used the same principles as Smith described except that a solid steel recording wire was wound around a rotating drum. The Telegrafon was similar in appearance and operation to Thomas Edison’s phonograph, with the recording method being magnetised wire as opposed to grooves in wax.

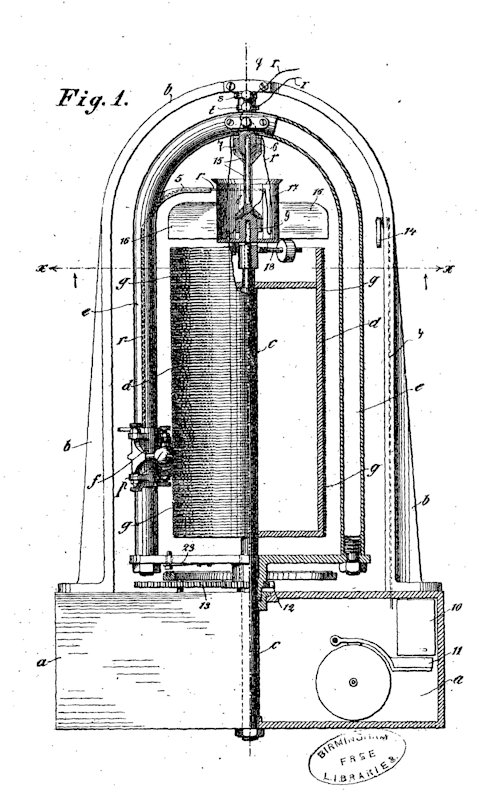

Schematic drawing from Valdemar Poulsen’s 1900 British patent (No.8961)

A working example of the Telegrafon was presented at the 1900 Paris World Exhibition and a few years later the American Telegraphone Company began commercial production of the device in the United States of America. The initial use of the Telegrafon was as an answering machine that, when coupled with a telephone, could play a pre-recorded message to the caller and record messages when the receiving party was unavailable. They were also sold as scientific instruments and office dictation machines. However, magnetic wire recorders couldn’t compete in a market already dominated by well-established phonographs and dictaphones. Wire recorders largely went under the radar over the next few decades.

Birth of the modern wire recorder

It wasn’t until the Second World War that the technology was revived due to developments instigated by the Armour Research Foundation in Illinois, USA. Armour Research developed wire recorders for the United States Navy as the devices and recording media were far more compact, robust, and simple to use than previous phonographic technologies. Wire offered a similar quality of sound reproduction without the characteristic playback hiss of phonograph records. Their portability was once demonstrated by a radio reporter who recorded himself while parachuting from an aircraft with a wire recorder strapped to his chest.

Webster-Chicago Wire Recorder 80-1 [1987.49] Museum of Transport and Technology (MOTAT).

The Webster-Chicago Wire Recorder 80-1 in MOTAT’s collection was made during the late 1940s. The Webster-Chicago Corporation was licensed to produce wire recorders for the war effort using technologies developed by the Armour Research Foundation. After the end of the war in 1945, like many other wartime manufacturers, Webster-Chicago switched to manufacturing and developing products for private consumers. The model 80-1 was released around 1947. It was a relatively basic model and was the precursor to the 180-1 Electronic Memory. These devices were marketed for domestic use and allowed users to record music from their radios and record players either via the supplied microphone, or by connecting directly through an audio input jack. The additional entertainment factor of recording one’s own voice or musical performances with the microphone was a selling point and many home devices were used in party games.

Wire Spools, Webster-Chicago Wire Recorder 80-1 [1987.49] Museum of Transport and Technology (MOTAT).

Webster-Chicago wire recorders record onto a thin stainless-steel wire approximately 100 microns thick, about the thickness of a human hair. The steel used has a high chromium content that helps prevent corrosion. The wire is wound around spools and passed over a magnetic recording head at approximately 24 inches per second (approximately 0.6m/s). Each spool can hold about 7200ft (2.2km) of wire, which results in around an hour of recording time. The wire feeds onto a drum of larger diameter than the spool. The larger size helps prevent the wire from snarling and tangling as the drum can spin at a slower speed relative to the spool. Additionally, the recording head moves up and down as the machine operates so that the wire can feed evenly across the spool/drum. The unit is supplied with a high impedance crystal microphone, which uses a piezoelectric crystal to generate the electric signal that is sent to the recording head. The user can play back recordings via the inbuilt speaker or by connecting an external device through the output jack.

Webster-Chicago had a brief peak in wire recorder sales from the late 1940s through the 1950s before the company collapsed in the 1960s. This mirrored the fate of wire recorders in general, which were outcompeted by the rapidly emerging magnetic tape industry.

Magnetic tape

Magnetic tape was invented by Fritz Pfleumer in Germany in 1928. Pfleumer’s early patents described a magnetic recording medium consisting of iron-oxide or steel powder pasted on to a strip of non-magnetic material such as paper or cellulose film. Alongside this, Pfleumer invented the first tape recording machine to record and playback his tape. This magnetic tape recorded sound in a similar way to previous wire recording technology but using the new tape medium.

In the early 1930s Pfleumer sold the rights to his invention to AEG (Allgemeine Elektricitäts-Gesellschaft AG, the ‘German General Electric Company’) which refined the technology. AEG released the first industrially produced tape recorder/player machines in 1935, known as the Magnetophon. While AEG focussed its attention on the mechanical aspects of the tape machine, development of the tape itself was outsourced to the BASF division of the chemical company IG Farben. BASF developed a tape consisting of a cellulose acetate base layer to which the magnetic iron oxide particles were chemically bonded via a solution of acetone and cellulose acetate. Various iron oxides were used through the evolution of BASF’s magnetic recording tape including carbonyl iron and magnetite before gamma iron oxide was settled on as it was more magnetically stable. In the early 1940s BASF scientists also developed a new plastic PVC (Polyvinylchloride) tape in which the iron oxide particles were mixed within the plastic prior to setting, thus removing the need to coat the tape. However, this initially produced a tape with weaker magnetic capabilities. Despite all these technological advancements, magnetic tape-recording technology wasn’t actively exported from Germany, so it remained largely unknown to the rest of the world until the end of the Second World War.

After the Second World War, German Magnetophon tape machines were acquired by allied forces and were studied, replicated, and refined by engineers, particularly in the United States of America. These machines were used in radio broadcasting and military applications prior to the development of private consumer devices in the late 1940s. Consumer reel-to-reel tape machines occupied a similar niche to that of the wire recorder and were utilised as dictation and personal recording devices. It wasn't until the 1950s that recording companies began producing and releasing pre-recorded popular music on tape, typically on 5- and 7-inch reels. This provided consumers with a new and improved way to listen to their favourite artists at home in high fidelity. Coupled with this, the technology proliferated throughout the world due to tape being more economical to produce and its physical properties made it much easier to handle than wire.

The Soundmirror was the first domestic tape machine produced in the world. It was developed in the United States of America by the Brush Development Company and was released in 1947. The machine was based on Pfleumer’s pre-war patents as Brush was not yet aware of the more advanced technology of the Magnetophon machines. The first Soundmirrors used a paper-backed magnetic tape which was quite fragile and readily shed the magnetic oxide powder. The machines required regular cleaning due to clogged recording heads. Once Magnetophon-derived technologies began appearing on the market, Brush’s Soundmirror devices rapidly became obsolete.

Soundmirror Tape Recorder [1966.322] Museum of Transport and Technology (MOTAT).

The Soundmirror tape recorder in MOTAT’s collection was made by Thermionic Products Limited. Thermionic Products Ltd was licenced by the Brush Development Company to manufacture Soundmirrors in the United Kingdom from 1948. This unit appears to be a model TP414 portable tape recorder/player from about 1951. It uses 7-inch tape reels and came with an ACOS crystal microphone. The unit is controlled with a gear-lever style switch and several knobs.

Magnetic disc

Another implementation of magnetic recording was in the disc recorder. This was initially devised and patented in 1901 by Peder Oluf Pedersen, a business partner of Valdemar Poulsen and Chief Engineer of the Aktieselskabet Telegrafonen (Danish Telegraphone Company). The disc telegraphone offered a different configuration to the wire telegraphone. The disc format was simpler to use, but required specially manufactured discs as opposed to wire, which was already manufactured for other applications. While some disc telegraphones were produced in Denmark, it was the American Telegraphone Company that had more success with marketing this machine. However, despite their advantages, these devices were unsuccessful as they were expensive to produce and offered significantly shorter recording times than wire telegraphones or standard phonographs.

Like the wire recorder, there was renewed interest in the magnetic disc recorder in the 1940s and it was redeveloped to take advantage of the emerging magnetic tape media technology. The Brush Development Company developed a magnetic disc recorder known as the Mail-A-Voice, which was released in 1946. These machines used the same recording material as magnetic tape but in a disc format. The recording head was positioned on an arm that lay over the rotating disc. The operation of the machine is visually similar to how a record player functions. The 9-inch diameter paper-backed discs could be folded and posted as an audio letter. These devices were used as dictation machines and proved quite useful for travelling salespeople to send recorded messages back to the office. Later makes and models moved to the more resilient plastic-based media similar to tapes. However, these couldn’t be folded and posted in the same way. Thermionic Products Ltd was again a licensee of Brush technology and marketed models in the UK under the name Recordon.

Mail-A-Voice Disc Recorder BK-503 [1970.206.2] Museum of Transport and Technology (MOTAT).

While magnetic tape continued to grow in popularity in the audio industry, magnetic discs found a niche and were developed in the fledging computer industry for data storage. Magnetic discs continue to be used in computer hard-drive technology to this day.

Compact cassette

In 1963 the Dutch electronics company Philips released the Compact Cassette, which miniaturised the existing reel-to-reel tape format and enclosed the reels within a plastic cassette. This greatly improved the accessibility of tape recordings, making them simple to use and portable. The small size of the Compact Cassette meant a compromise in the audio quality as compared to the much larger open reel systems. To the average consumer, however, the benefits of having an easy-to-use system and an expanding catalogue of popular recordings to purchase and play meant the Compact Cassette gained widespread popularity. It became the de facto standard in consumer music recording for several decades.

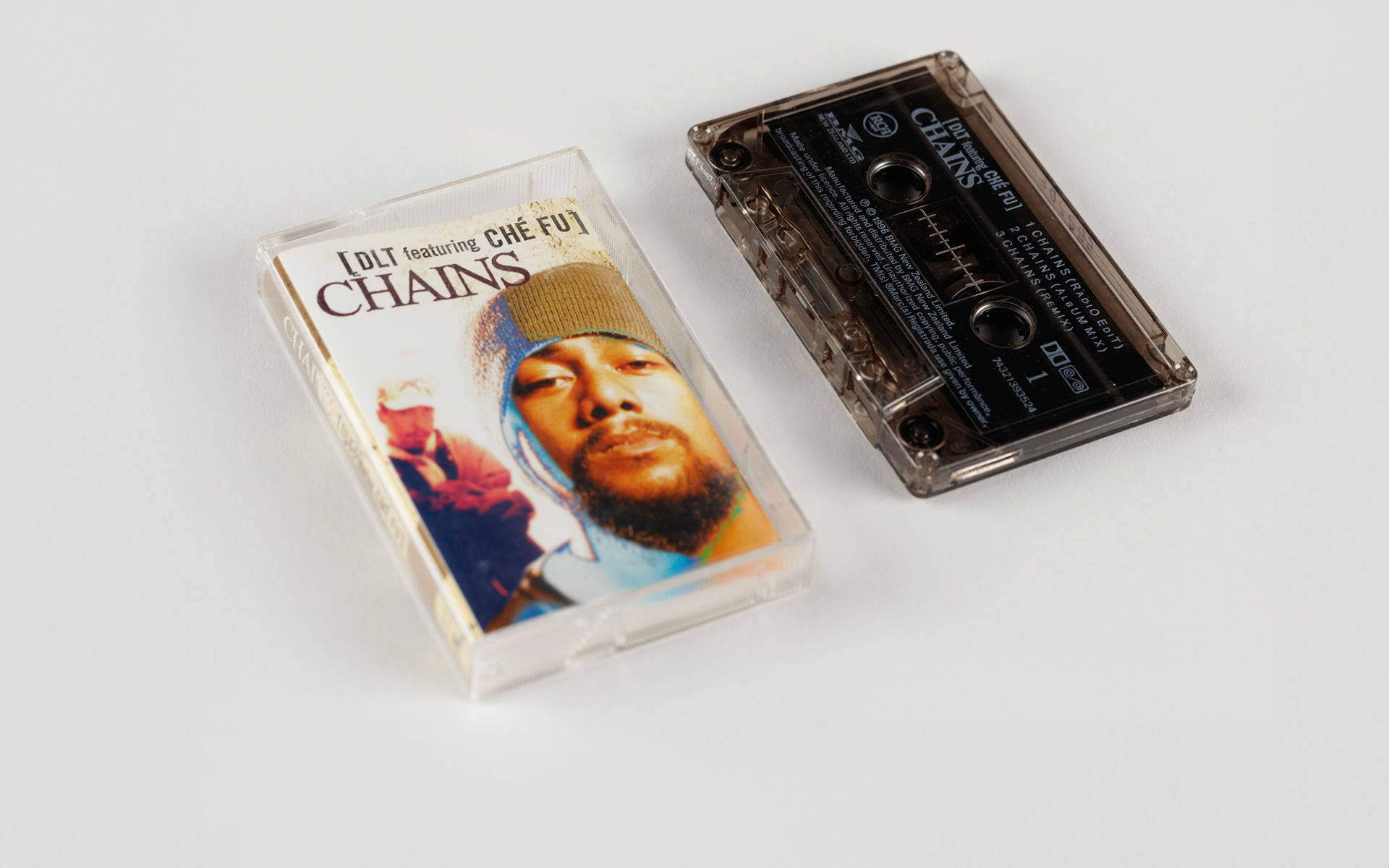

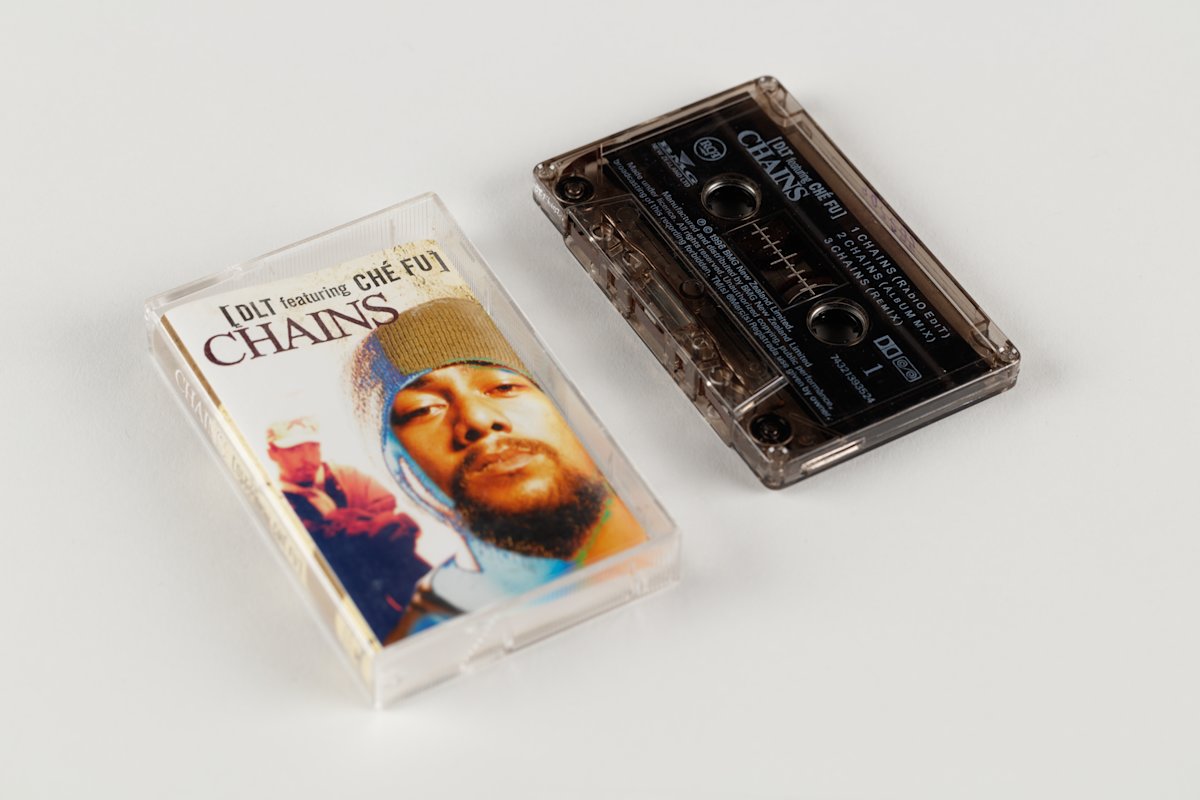

Compact Cassette [Chains, DLT featuring Che Fu] [2019.120] Museum of Transport and Technology (MOTAT).

The digital era

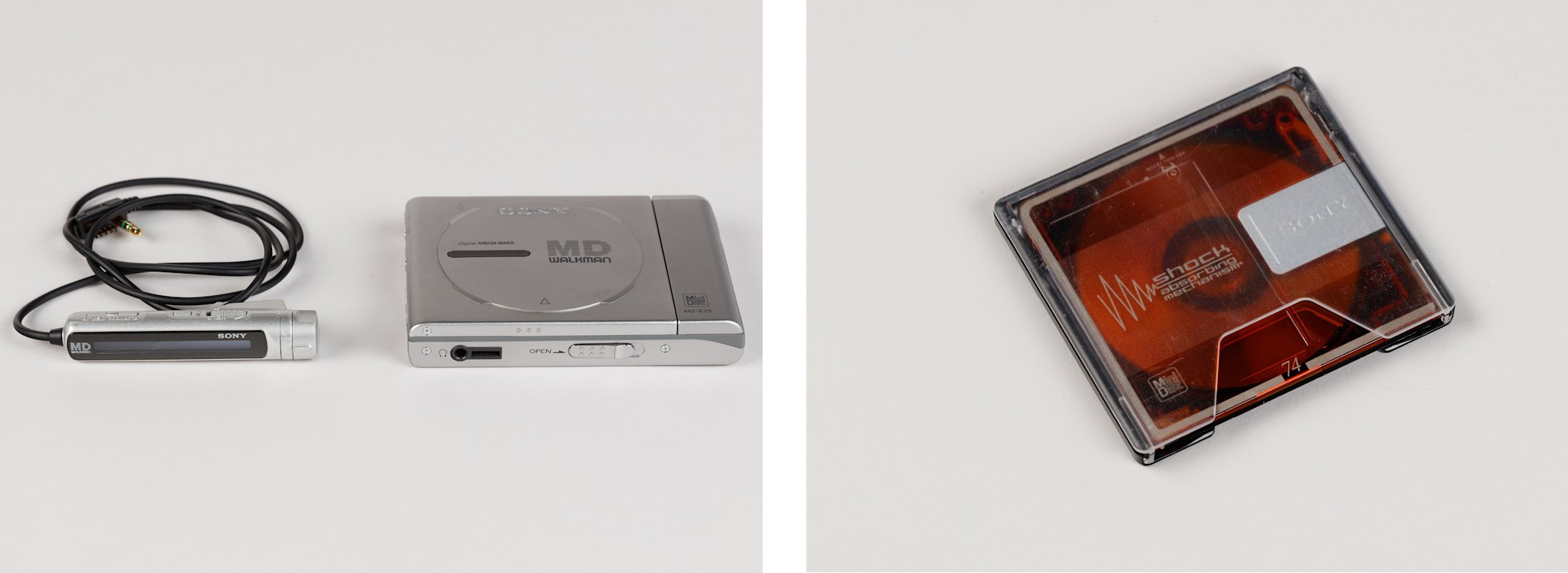

The next major step in consumer audio technologies was the development of optical discs such as the Compact Disc (CD). CDs became prevalent in the audio industry through the 1990s and effectively replaced the Compact Cassette as the preferred medium for consumer music recording. This period also saw the development of technologies that competed with CDs, namely Digital Compact Cassettes (DCC) and MiniDiscs. Both were digital recording technologies released in late 1992. DCC was an evolution of Compact Cassettes whereas MiniDisc was a new innovation using magneto-optics. Magneto-optical recording systems such as the Sony MiniDisc use a laser to heat the recording surface to a temperature that makes it susceptible to magnetic polarisation. A magnetic recording head then polarises the heated material. As the surface cools, the magnetic record becomes fixed. An optical laser is then able to read changes in the polarity of the MiniDisc as the laser reflects light differently depending on the polarisation.

DCC was developed to be backwards compatible with Compact Cassettes in that both analogue and digital cassettes could be played on a DCC machine. While this allowed people to retain their existing collections of Compact Cassettes, it did require the replacement of existing tape machines to make use of the new digital technology. MiniDisc was more successful than DCC as it offered a new and novel way of playing and recording music. MiniDisc also had a strong focus on portability with many devices being released under Sony’s Walkman brand. Conversely, DCC started out with home stereo machines before exploring portable music devices. Like tape and wire recorders before them, a key aspect of MiniDiscs was their re-writability and they could be used to create a mixtape, recorded onto from external sources such as radio, tapes, CDs, live performances, or even with your own voice. Ultimately though, the fate of the MiniDisc mirrors that of its wire recorder ancestors. DCC and MiniDisc couldn’t compete in the digital audio market, losing out first to CDs then to digital media devices such as MP3 players and iPods.

Left: Sony MiniDisc MZ-E25 Walkman [2023.157.1]; Right: Sony MiniDisc [2023.157.2]. Museum of Transport and Technology (MOTAT).

Audio recording and listening devices have largely moved on from magnetic technologies in favour of solid-state drives (SSD). However, magnetic audio recording technology is still used by some audiophiles, hobbyists, and boutique recording studios and radio stations. Magnetic data storage remains prevalent in other areas, specifically in computer storage such as hard disk drives (HDD) and tape storage drives, as well as items like swipe cards (e.g. bank and access cards).

Story by Callan Bird, Curator – Technology (MOTAT).

Story edited by Nicola Jennings, Senior Curator – Technology (MOTAT).

Published May 2024

Sources

Clark, M., & Nielsen, H. (1995). Crossed wires and missing connections: Valdemar Poulsen, The American Telegraphone Company, and the failure to commercialize magnetic recording. The Business History Review, 69(1), 1–41. https://doi.org/10.2307/3117119

Clayman, A. (2024). Webster-Chicago Corp., est. 1914. Made in Chicago Museum. https://www.madeinchicagomuseum.com/single-post/webster-chicago/

Engel, F., & Hammar, P. (2006, August 27). A selected history of magnetic recording. Richard L. Hess. https://www.richardhess.com/tape/history/Engel_Hammar--Magnetic_Tape_History.pdf

Greatbear audio & video digitising. (2023). Paper-backed Soundmirror 'magnetic ribbon' - early domestic magnetic tape recorders. https://thegreatbear.co.uk/audio-tape/paper-backed-magnetic-ribbon-early-domestic-magnetic-tape-recorders/

Jones, B.M. (2013). Thermionic products. Brenell tape-recorders. http://brenelltape.co.uk.websitebuilder.prositehosting.co.uk/thermionic-products

Kadis, J. (2014). Magnetic recording: Analog tape [Lecture notes]. https://ccrma.stanford.edu/~jay/subpages/Lectures/Lecture7-Magnetic_recording.pdf

Ley, W. (1965, August). For your information. Galaxy Magazine, 23(6), 139-142. https://archive.org/details/Galaxy_v23n06_1965-08/page/n139/mode/2up?view=theater

Made on Tape. (2021, April 7). What is a wire recorder? Webster-Chicago "Electronic Memory" model 228-1 [Video]. YouTube. https://www.youtube.com/watch?v=f5rcuuuV8F8

Morton, D. (1998, April). Armour Research Foundation and the wire recorder: How academic entrepreneurs fail. Technology and Culture, 39(2), 213-244. https://doi.org/10.2307/3107045

Morton, D. (2024). Wire recorders in World War II. History of sound recording technology. https://recordinghistory.org/technology/the-wire-recorder/wire-recorders-in-world-war-ii/

Museum für Kommunikation Frankfurt, Museumsstiftung Post und Telekommunikation. (n.d.). Laying down sound: early recording inventions from wire to tape [Online Exhibition]. https://artsandculture.google.com/story/rQVBzAgrGcvPKQ

Museum of Magnetic Sound Recording. (2018). Manufacturer profiles. https://museumofmagneticsoundrecording.org/ManufacturersBrush.html

Museum of Magnetic Sound Recording. (2018). Oberlin Smith. https://museumofmagneticsoundrecording.org/EducationOberlinSmith.html

National Museum of American History. (n.d.). Telephone answering machine component. https://americanhistory.si.edu/collections/nmah_1301345

Pedersen, P. (1902, November 13). Improvements in magnetizeable bodies for use in telegraphones [UK Patent No. 23738]. European Patent Office. https://worldwide.espacenet.com/publicationDetails/biblio?CC=GB&NR=190123738A&KC=A&FT=D&ND=3&date=19021113&DB=EPODOC&locale=en_EP

Pfleumer, F. (1930, June 26). Lautschriftträger [German Patent No. 500900]. European Patent Office. https://worldwide.espacenet.com/publicationDetails/biblio?CC=DE&NR=500900C&KC=C&FT=D&ND=3&date=19300626&DB=EPODOC&locale=en_EP

Poulsen, V. (1899, October 31). Telegrafon (Danish Patent No. 2653). European Patent Office. https://worldwide.espacenet.com/publicationDetails/biblio?CC=GB&NR=189908961A&KC=A&FT=D&ND=3&date=19000317&DB=EPODOC&locale=en_EP

Poulsen, V. (1900, March 17). Method of and apparatus for effecting the storing up of speech or signals by magnetically influencing magnetisable bodies (British Patent No. 8961). European Patent Office. https://worldwide.espacenet.com/publicationDetails/biblio?CC=DK&NR=2653C&KC=C&FT=D&ND=3&date=18991113&DB=EPODOC&locale=en_EP

Ratazzi, E. P. (2004, December 15). MiniDisc: Successful innovation or just cool technology?: An analysis of Sony’s decade-long quest for success. Air Force Research Laboratory, Rome, New York. https://www.researchgate.net/profile/Paul-Ratazzi/publication/242507825_An_Analysis_of_Sony's_Decade-Long_Quest_for_Success/links/02e7e5295ffbf2a5e8000000/An-Analysis-of-Sonys-Decade-Long-Quest-for-Success.pdf

Redlich, G. (2003/2024). Magnetband-Museum. http://www.magnetbandmuseum.info

Science Museum Group. (2024). Soundmirror tape recorder model TP 411, c.1950. https://collection.sciencemuseumgroup.org.uk/objects/co8635237/soundmirror-tape-recorder-model-tp-411-c-1950-tape-recorder

Smith, O. (1888, September 8). Some possible forms of phonograph. The Electrical World, XII(10), 116-117. https://books.google.co.nz/books?id=zYVMAAAAYAAJ&pg=RA3-PA116#v=onepage&q&f=false

Southwest Museum of Engineering, Communications and Computation. (2004, September 8). Wire recorder care & repair. https://smecc.org/wire_recorder_care_&_repair.htm

youtuuba. (2017, December 1). Webster Chicago model 80-1 wire recorder [Video]. YouTube. https://www.youtube.com/watch?v=7Y6XLETWbqM