1930s Kiwi steam invention made our butter better

![MOTAT’s Vacreator on display at MOTAT circa 1990. Murray Deodorizers Limited. 1961. 1990. Vacuum Pasteuriser [Vacreator, sectioned model], 1990.14. The Museum of Transport and Technology (MOTAT).](https://images.ctfassets.net/mplktqcfflsk/61nipy1eZB8CRNdAvriTno/70f6d654f2b169c923983b7234bfca57/IMAGE_1_1990.14_p4.JPG?w=770&h=716&fl=progressive&q=85&fm=jpg&bg=transparent)

MOTAT’s Vacreator on display at MOTAT circa 1990. Murray Deodorizers Limited. 1961. 1990. Vacuum Pasteuriser [Vacreator, sectioned model], 1990.14. The Museum of Transport and Technology (MOTAT).

What is a Vacreator?

A Vacreator is a vacuum unit in which cream and steam are mixed at a high temperature (89-98 degrees Centigrade), which both pasteurises (kills micro-organisms) and deodorises (removes unwanted smells and tastes) the cream. The cream is then flash-cooled under vacuum pressure. At the end of this process, the final product is an odourless, neutral-tasting cream, which can then be made into high-quality butter.

How was it invented?

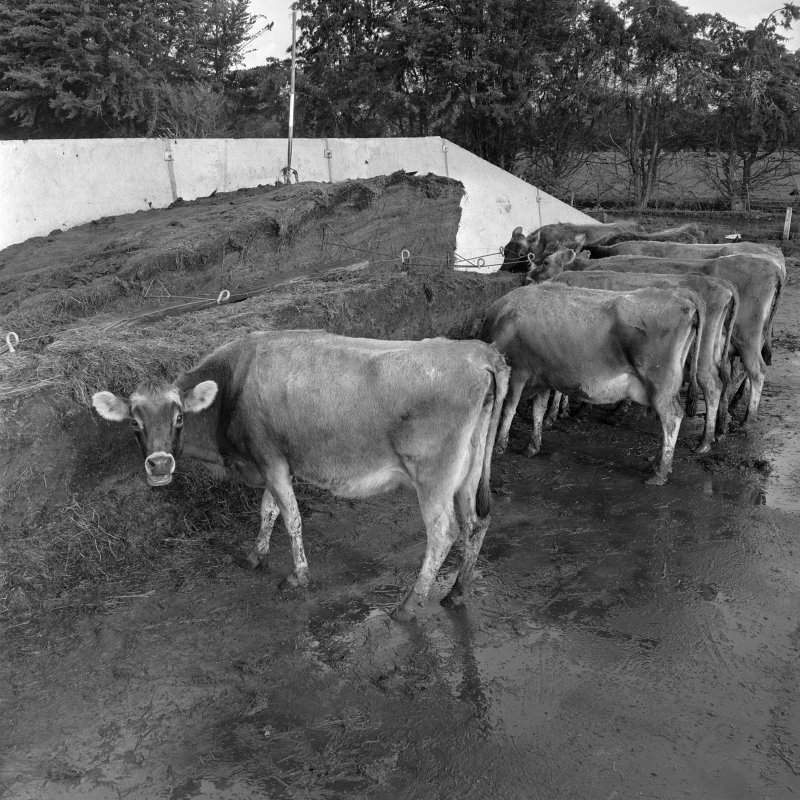

Work to design, develop and make a Vacreator started in 1923, when Henry Lamont Murray and Frank S. Board were about to open a butter factory in Te Aroha. At the time, the price paid to farmers for cream depended on its quality. Murray and Board hoped to be able to buy lesser quality cream and use it to make high-quality butter using their innovative vacreation process. With strong flavours – due to the cows’ diet of poor-quality pasture – removed from the cream, they could make a better-quality butter, which would return a higher price from the overseas market. This process was significant in further developing the butter trade between Aotearoa New Zealand and the United Kingdom in the early-mid twentieth century.

Cows eating hay. Ron Vine. 1963. Hauraki plains farms, Sept 1963, 10/012/106. Walsh Memorial Library, The Museum of Transport and Technology (MOTAT).

Murray's original process consisted of passing hot cream from conventional flash pasteurisers through a deodorising vessel maintained under vacuum. Early trials, soon after the Te Aroha Dairy Company opened, showed that flavours could be removed by this method. This was encouraging and resulted in good-quality butter being produced for export. The process continued to be refined, and in 1927 live steam was introduced directly into the cream as it travelled from the flash pasteuriser to the deodorising vessel, which further improved the deodorising.

As the Waipa Post reported on 5 April 1927: "The dairy herds pick up many essential oils from ordinary pastures, and stronger odoured oils when the cows are fed on root and forage crops. The idea of the inventors is to abstract this taint or flavour from the finished product, and it is considered by local experts that the finest cream arriving at the factory can be improved by the new treatment."

In 1929, Murray Deodorisers Limited was formed to take over from Te Aroha Dairy Company Limited. Their business focused on developing the vacreation process and equipment further and promoting Vacreator sales. The increased availability of industrial-grade stainless steel, by the late 1920s, made manufacturing the machines easier and quicker. Early evidence from operators and farmers indicated a much-improved product was achieved after cream was put through the vacreation process. Henry Lamont Murray worked as Managing Director of the company and spearheaded research and development of the original Vacreators, with his next step to make use of the deodorising steam to pasteurise the cream as well.

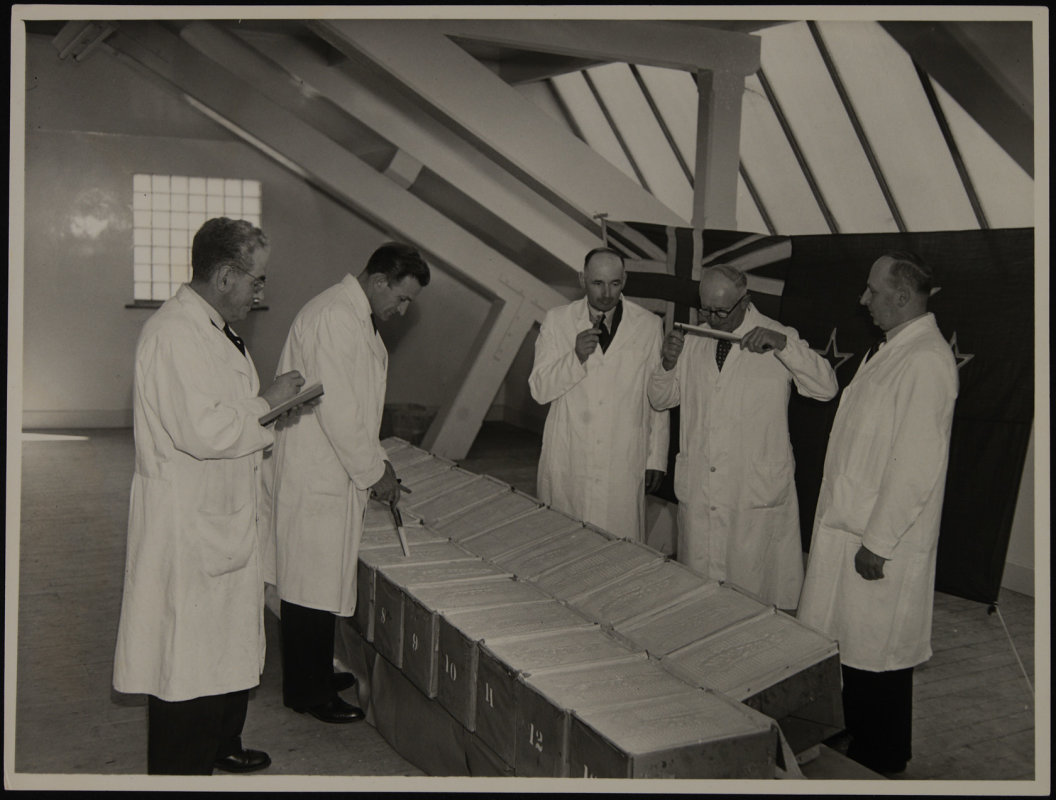

Early experiments to do this showed the early Vacreators worked well in conjunction with deodorisers, and the combined machine’s advantages over previous pasteurisation methods were that it cost less to operate, had potentially greater capacity, and, by adding a second vacuum vessel, the new process minimised the 10% to 15% dilution of the cream resulting from the injected steam. By early 1931, the Waikato Times was reporting that Murray’s refinements to the Vacreator were being "enthusiastically approved by the Governments of Australia, and the South African Union, and ha[d] also been installed in many dairy factories in the United States as well as in New Zealand." By 1933, the first fully developed Vacreator was in operation at Northern Wairoa Cooperative Dairy Company in Dargaville.

An advertising poster for Anchor butter. Anchor et al. 1930s. 'Anchor' Butter For the best of Guests - Your Family!, ART-2019-11. Walsh Memorial Library, The Museum of Transport and Technology (MOTAT).

After the technology was mastered, variations of Vacreator models soon followed. A “Baby Type” Vacreator, with a capacity of 2500 pounds (1133kg) of cream per hour, the “Junior Type”, which doubled this capacity, and the “Standard M”, which tripled the Junior Type capacity, were on the market. Following its success in Aotearoa New Zealand, it appears the first Vacreator was sold to the Public Health Service, a government agency in the United States of America, for evaluation and trials in September 1938. However, final approval by the United States Public Health Service for food use was not granted until 1954. Prior to this, on 28 September 1934, Murray Deodorisers Limited filed a U.S. Federal trademark application for a Vacreator trademark. This trademark was assigned a Serial Number (#71356566) by the United States Patent and Trademark Office (USPTO), which expired in 1996. In addition, on 28 March 1946 another Serial Number (#71499142) was assigned, which expired on 11 March 1992.

Testing or grading the butter for quality and taste. Unknown photographer. [1960s]. [Five men in white coats testing dairy product], 12-0923. Walsh Memorial Library, The Museum of Transport and Technology (MOTAT).

Entering the MOTAT Collection

MOTAT’s example is a refurbished, sectioned model reconstructed from an original machine during 1989/1990 by Protech Engineering Limited. The original machine was installed at the Tauranga Butter Factory in 1961. It was later moved to a factory in Katikati, then to Te Puke, before finally ending up in Edgecumbe at the Rangitāiki Plains Dairy Company (trading as Bay Milk Products). It was used for several decades by this company, however during the Edgecumbe earthquake on 2 March 1987 the company’s two Vacreators were damaged. The other machine was able to be repaired and become operational again, but this one had badly damaged internal mechanisms and was deemed uneconomical to repair to working order.

Fortunately, instead of being scrapped, in mid-1989, the Rangitāiki Plains Dairy Co. contacted MOTAT’s Executive Committee to gauge interest in refurbishing the damaged Vacreator for display. This was enthusiastically received and in the following months a project was set up under the guidance of David Gardiner of Protech Engineering Limited. Gardiner worked with around eight dairy companies, the New Zealand Dairy Board, and individuals in the dairy industry, to research, rebuild, fundraise, and transport the sizeable Vacreator to MOTAT.

This Vacreator arrived in Tāmaki Makaurau Auckland during the start of 1990 and was initially displayed in MOTAT’s Energise display, an exhibition drawn from MOTAT’s extensive collections, which showcased energy technology and its impact on society. Four themes were highlighted: Energy in the Home, Energy in the Workplace, Generators and Convertors, and Energy on the Move, with partial sponsorship for the exhibition provided by the Ministry of Energy. Alongside the Vacreator were industrial lathes, petrol pumps, the McLaren traction engine and the Aveling diesel roller.

In December 1990, an event to recognise engineering innovation was held at MOTAT by the Institute of Professional Engineers of New Zealand (IPENZ). This was part of the country’s 150th commemoration of the signing of the Treaty of Waitangi. The December event culminated in 68 notable and significant engineering projects, sites, industries, and infrastructures being identified as having an impact on the development of Aotearoa New Zealand, and these were commemorated by having bronze plaques presented by IPENZ. Included is the Vacreator at MOTAT.

Ninety years on from being invented, the technology in Vacreators remain key to consistent cream quality, which in turn makes tasty, high-quality butter. Vacreators are still manufactured by dairy machinery companies and are used by dairy companies around the world.

Authors: Megan Hutching & Belinda Nevin

Editor: Nicola Jennings

Published April 2024